Introduction

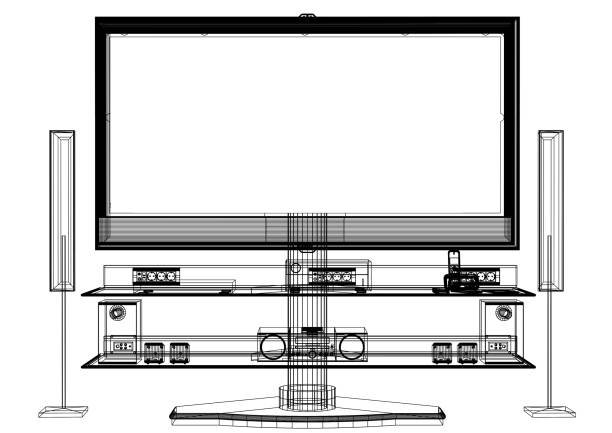

A 3D printed Vizio TV riser is an excellent way to enhance your entertainment setup by raising your television to a more comfortable viewing height. Whether you’re looking to improve ergonomics, create additional space, or achieve a sleek, customized look, 3D printing offers a cost-effective and personalized alternative to store-bought TV risers. This guide will walk you through the benefits, materials, and steps to design and print your own Vizio TV riser.

Why Use a 3D Printed TV Riser?

1. Customization for Your Setup

With a 3D printed TV riser, you can design the exact height, width, and shape that best fits your Vizio TV and entertainment unit.

2. Reasonably priced substitute

Particularly for premium or custom models, purchasing a TV riser can be costly. Creating a working riser for a fraction of the cost is made possible with 3D printing.

3. Enhanced Space Effectiveness

Underneath for extra hardware including soundbars, gaming consoles, remote storage, or cable management is a TV riser.

4. Ergonomic Advantage

Particularly for long screen time, elevating your TV to eye level helps to ease neck strain and increase viewing comfort.

5. Modern and elegant styles

To complement your home décor, 3D print a decorative riser, geometric riser, or simple one.

Selecting Correct Material for Your 3D Printed TV Riser

Stability and lifetime depend on choosing the correct 3D printing material. Here are the best options:

1. PLA (Polylactic Acid)

- Pros: Easy to print, affordable, widely available.

- Cons: Less durable and heat-resistant than other materials.

- Best for: Small, lightweight TV risers in low-heat environments.

2. PETG (Polyethylene Terephthalate Glycol-Modified)

- Pros: Stronger and more durable than PLA, impact-resistant, slightly flexible.

- Cons: Requires a higher print temperature, prone to stringing.

- Best for: Medium-sized risers supporting heavier TVs.

3. ABS (Acrylonitrile Butadiene Styrene)

- Pros: High durability, heat-resistant, strong.

- Cons: Requires a heated bed and proper ventilation.

- Best for: Large, high-strength TV risers.

4. Carbon Fiber-Reinforced Filament

- Pros: Extremely rigid, lightweight, and durable.

- Cons: Requires a hardened steel nozzle, higher print temperature.

- Best for: Professional-grade, heavy-duty TV risers.

How to Design a 3D Printed TV Riser

1. Measure Your TV and Entertainment Space

- Measure the width and depth of your Vizio TV stand.

- Decide on the desired height for optimal viewing.

- Consider additional clearance space for devices underneath.

2. Use 3D Modeling Software

- Tinkercad (Beginner-friendly, browser-based)

- Fusion 360 (Professional-grade, precise modeling)

- Blender (Best for complex, artistic designs)

3. Design for Stability and Strength

- Use thicker walls and solid infill for durability.

- Add reinforced legs or support structures.

- Consider a hollowed-out design to reduce filament usage without compromising strength.

4. Export Your File in STL Format

Most 3D printers use STL files, which you can generate from your CAD software before slicing.

Best 3D Printer Settings for a TV Riser

1. Layer Height

- 0.2mm – 0.3mm for a balance between strength and print speed.

2. Infill Density

- 30-50% infill for a solid, load-bearing riser.

3. Print Speed

- 50-70mm/s for best results (avoid high speeds to prevent layer adhesion issues).

4. Bed Adhesion

- Use a heated bed (60-100°C depending on material).

- Apply a brim or raft to prevent warping.

5. Supports

- Enable supports if your design includes overhangs or elevated sections.

Post-Processing Your 3D Printed TV Riser

1. Sanding and Smoothing

- Use 400-800 grit sandpaper to smooth layer lines.

- Apply acetone smoothing (for ABS) or use a heat gun for PETG smoothing.

2. Painting and Finishing

- Use acrylic paint or spray paint for color customization.

- Apply a clear coat or sealant for extra durability.

3. Assembly and Installation

- Secure multiple parts together with super glue, screws, or snap-fit connectors.

- Ensure even weight distribution by placing your riser on a flat, stable surface.

READ MORE: 3D Printing a Christmas Star: A Festive DIY Guide

FAQs

1. How strong is a 3D-printed TV riser?

With the right material and print settings, a well-designed 3D-printed TV riser can support medium to large TVs, especially if made with PETG, ABS, or carbon fiber filament.

2. Can I print a TV riser on a budget 3D printer?

Yes! Entry-level 3D printers like the Ender 3 or Anycubic i3 Mega can print a functional TV riser, though larger prints may require assembly.

3. How long does it take to 3D print a TV riser?

Print time depends on the size, material, and settings, but expect 8-20 hours for a single-piece riser and longer for multi-part designs.

4. Is a 3D-printed TV riser safe for heavy TVs?

Yes, if printed with strong materials and reinforced design, it can safely hold large Vizio TVs, though testing is recommended before long-term use.

5. Where can I find free 3D models for a TV riser?

Websites like Thingiverse, MyMiniFactory, and Cults3D offer free and paid TV riser STL files for 3D printing.

Conclusion

A 3D printed Vizio TV riser is a customizable, budget-friendly, and stylish solution for elevating your TV. Whether you need better ergonomics, extra storage, or a sleek entertainment setup, designing and printing your own TV riser allows you to achieve the perfect fit for your home.

With the right materials, printer settings, and post-processing techniques, you can create a sturdy and aesthetically pleasing riser that enhances your viewing experience.