Introduction:

One of the most common issues when 3D printing with PLA is curled edges, where parts of the print lift from the bed, causing an uneven surface. Warping can affect the final print quality, structural integrity, and adhesion to the print bed. Fortunately, there are multiple solutions to help flatten curled edges and achieve a smooth, even 3D print.

This guide will explore why PLA prints curl, how to fix curling, and best practices to prevent warping in the first place.

Why Do PLA Prints Curl at the Edges?

1. Poor Bed Adhesion

If the first layer does not stick well to the print bed, the corners or edges may lift, causing warping.

2. Uneven Print Bed

A non-level print bed creates inconsistencies in the first layer, leading to curled edges.

3. Incorrect Print Temperature

- Too high nozzle temperature → PLA expands and shrinks rapidly, leading to warping.

- Too low bed temperature → PLA does not adhere properly to the bed.

4. Cooling Too Fast

- If PLA cools too quickly, uneven contraction can lift edges off the print bed.

- Strong fan cooling may cause layers to contract too fast.

5. Printing in a Drafty Environment

- Air conditioning, fans, or open windows can cause inconsistent cooling.

- Uneven cooling leads to edge curling.

How to Flatten Curled Edges in PLA Prints

1. Increase Bed Adhesion

- Use adhesion tools like glue sticks, painter’s tape, or PEI sheets.

- Set your first layer height slightly lower for better grip.

2. Level the Print Bed Properly

- Manually adjust bed leveling screws or use an auto-bed leveling sensor.

- A level bed ensures even first-layer extrusion, preventing curling.

3. Adjust Print Temperature

- Recommended settings for PLA:

- Nozzle temperature: 190-220°C

- Bed temperature: 50-70°C

- Experiment with slightly lower nozzle temperatures to minimize shrinkage.

4. Slow Down Cooling Fan Speed

- Reduce fan speed to 30-50% for the first few layers.

- Gradually increase cooling after layer 5 or 10.

5. Use a Brim or Raft

- Brims add an extra layer around edges to improve adhesion.

- Rafts create a solid foundation underneath the print.

6. Enclose the Print Area

- Use an enclosure to maintain a stable temperature.

- Block air drafts to prevent uneven cooling.

7. Adjust Print Speed

- Print the first layer slower (20-30mm/s) for stronger adhesion.

- Avoid very high speeds that may cause uneven extrusion.

8. Apply a Heat Gun or Hair Dryer

- If curling occurs after printing, apply gentle heat to reshape the part.

- Be careful not to overheat, as PLA may become deformed.

Preventing PLA Edge Curling in Future Prints

1. Maintain a Clean Print Surface

- Remove dust and grease using isopropyl alcohol (IPA) before printing.

2. Optimize First Layer Settings

- Increase first layer extrusion width for a strong foundation.

- Use a z-offset calibration to ensure proper squish onto the bed.

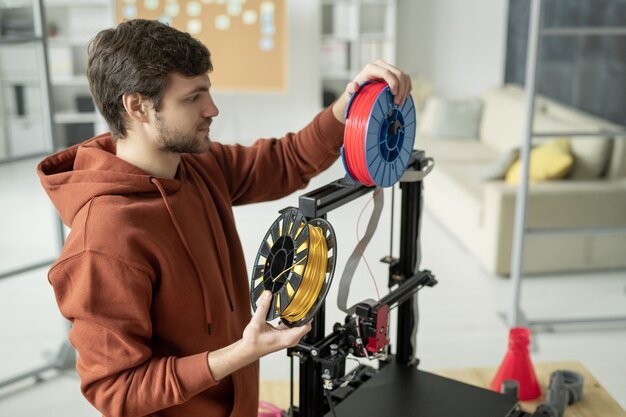

3. Store Filament Properly

- Keep PLA filament dry and sealed to avoid moisture absorption, which affects adhesion.

4. Experiment with Different Bed Surfaces

- Try glass beds, PEI sheets, or textured build plates to find what works best.

5. Monitor the Printing Process

- Watch the first few layers to ensure proper adhesion.

READ MORE – 3D Printed Vizio TV Riser: A Customizable and Cost-Effective Solution

FAQs:

1. Why does my PLA print warp even with a heated bed?

PLA can still warp if the bed isn’t hot enough, adhesion is poor, or cooling is too strong. Try increasing bed temperature and using a brim.

2. Can I fix a curled print after it has finished?

Yes! You can use a heat gun or warm water bath to slightly soften and reshape curled edges.

3. What’s the best adhesion method for preventing PLA warping?

A PEI sheet, glue stick, or painter’s tape are excellent for strong bed adhesion.

4. Does brand of filament impact PLA curling?

Yes. Better layer adhesion and less shrinking of high-quality PLA filaments help to lower curling.

5. Should I totally shut off the cooling fan?

No, although cutting it down for the first five to ten layers helps avoid curling. Then progressively speed up the fan.

Conclution:

Optimizing print settings, enhancing bed adhesion, and controlling cooling allows 3D printing PLA without curled edges. By following the troubleshooting steps in this guide, you can achieve smooth, warp-free prints and improve the overall quality of your 3D-printed parts.